|

Case Trimming Fixture

Completed 2/5/04

The tedium of

trimming many hundreds of 223AI fireformed cases led me to build

this simple fixture to greatly speed up the task. Since I

already had a small, ancient, Craftsman lathe, I decided to

build this fixture that allows a case to be trimmed by an end

mill held in the lathe chuck in less than five seconds. Total

cost was about $15.00 and a fun afternoon in the shop.

The idea was to

build a cantilevered arm that supports a form fitted guide or

collet, exactly fitting the fired cases to be trimmed. The case

will index of the shoulder of the fired case. The arm is

attached to the compound of the lathe, and adjusted so that a

case fully inserted into the holder will be exactly coaxial to

the spindle bore. A simple end mill held in the lathe chuck is

used to do the cutting. The precise amount of trim is very easy

to set, since the compound travel adjustment is calibrated. One

a case is just kissed with the cutter, the OAL is measured, and

the additional amount of trim is dialed into the compound.

The major problem was how to

support the holder rigidly, and still have it adjust it easily

and quickly over all the degrees of freedom necessary to get

perfect alignment. To this end, a crude but effective ball joint

holder was built using 1 ¼ inch iron pipe fittings, a round

plastic ball drawer handle, and other pieces of hardware.

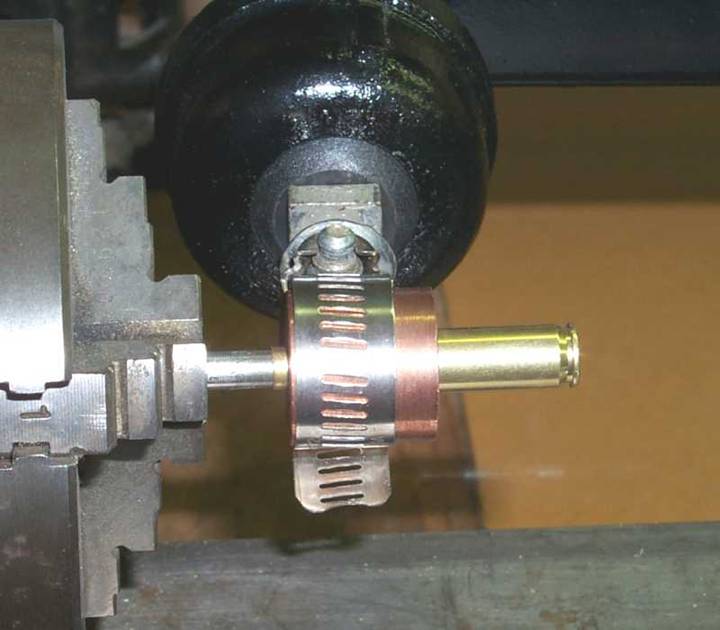

Rectangular steel

tubing was used to build the arm, with a simple T bolt method of

attachment to the compound tool holder slot. The ball joint uses

the plastic spherical handle captured between a 1 ¼ inch pipe

cap and plug. The plug is brazed to the arm, and a simple insert

cut from a PVC pipe fitting is used in the cup to provide a

non-marring positive lock on the ball. The pipe cap is turned on

the lathe to provide a chamfered clearance hole in the cap top

to allow a bolt threaded into the ball handle to protrude. The

bolt has a stainless hose clamp brazed to the head, and is used

to hold the form fitted case bushing.

The case bushing is

made using five minute epoxy, mold release agent, and a short

piece of ¾ inch copper pipe. After a case is coated with mold

release (I used Brownell’s aerosol release spray) , it is set

base down into a pad of modeling clay, and the copper pipe piece

carefully centered around the exposed case. Some five minute

epoxy is then mixed and poured into the void between the case

and the pipe, and allowed to cure. Once cured, the case extracts

easily, and the rough ends of the pipe-epoxy can be faced in the

lathe.

The result is a

bushing that exactly fits the fired cases, and allows the case

neck to slightly protrude past the epoxy for easy trimming.

Once the fixture is assembled

and mounted on the lathe compound, the process of alignment and

trim length adjustment is started.

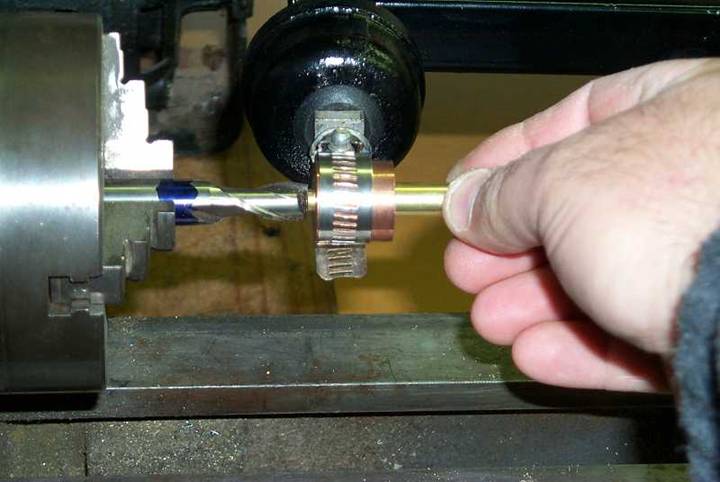

Using a bullet

minus 0.005” diameter mandrel in the lathe chuck, the fixture is

adjusted to allow a case fitted into the bushing to easily slide

on and off the mandrel as the carriage is traversed. It is easy

to tell when the case is misaligned, as the case will not rotate

freely in the bushing, or the fixture and case will bind on the

mandrel as the carriage is traversed. Once the cross slide and

ball joint adjustments are correct, the pipe cap is tightened to

lock the ball in place. The carriage is traversed away from the

chuck, and the alignment mandrel removed. An end mill is

inserted in the lathe chuck at this time.

Setting the

trimming depth of cut is now a very simple process. The carriage

is adjusted to bring the neck of a case inserted into the

bushing to a point where it is almost touching the end mill. The

carriage lock is then engaged, and case that needs trimming is

inserted into the bushing by hand. Set the lathe to turn at a

moderate rate of rotation. Slowly adjust the compound (set for a

0 degree angle of travel) until the cutter just kisses the case

neck. Measure the case length, and calculate the additional

depth of cut needed to achieve the desired length. Dial this

additional length into the compound, and you are ready to trim

cases.

I was able to trim

over 400 cases in less than an hour using this fixture. The

trimmed length never varied over a couple of dozen randomly

picked cases by more than 0.0005”. This is equal to the accuracy

of my hand operated Wilson case trimmer, and is much, much

faster. New bushings can be made for any case in a matter of

minutes. I found that rotating the case about a half turn during

the cutting operation made for a slightly cleaner cut, and also

eliminated any slant due to residual misalignment of the bushing

and the lathe axis of rotation. A two flute end mill is shown in

the above photos and works just fine, but I had slightly better

results (smoother cuts) with a four flute mill. The cuts are as

clean or cleaner than the Wilson trimmer, bright and shiny with

almost no burr. |