|

6.5-284

MAK TubeGun Target Rifle

Click For

Latest Updates

Completed 3/6/05

This rifle was a

multiple week project, most of which was spent building the

necessary fixturing and tooling necessary to do the action

blueprinting and the barrel fitting. All machining was performed

on a Grizzly 13X40 lathe, and a Grizzly 9X42 mill, by the

author.

The rifle was

chambered for Lapua brass. I expect to be using Lapua Scenar

bullets, in the 123 and 139 grain weights.

The specifications

are as follows:

|

Caliber |

6.5-284

Lapua Match |

|

Barrel |

Pac-Nor Stainless Super Match

grade, 29” finished length, 3 groove, 1 : 9” twist,

heavy varmint contour |

| Muzzle Brake |

Pac-Nor |

|

Reamer |

Dave Kiff of

Pacific Tool and Gauge – 6.5 X

284 Lapua Match, 0.297 neck, 0.120 freebore |

|

Receiver |

Remington M700 right hand short action. Receiver was

blueprinted; single point chasing of the receiver

threads, locking lugs, and receiver face. Bolt was

re-machined by truing the front and rear face of the

lugs, bolt nose and outside diameter, and bolt face. The

bolt had four small beads TIG welded where the receiver

raceway contacts the bolt body, which were subsequently

machined to provide 0.001” clearance when in battery. |

|

Trigger |

Jewel HVR |

| Stock |

Single Shot

TubeGun by

MAK Enterprises. Receiver is

bonded into the aluminum tube using J-B Weld epoxy |

|

Handgrip |

Sierra |

| Buttstock |

Ironstone competition model

with optional weights |

|

Scope |

Nightforce NXS 12-42X56 with

NP-1RR reticle |

|

Rings |

Leupold QRW high, 30MM |

| Weight |

19.5

pounds |

Performance

at 200 yards:

14 shots at 600 yards, windy conditions,

also 142 SMK/H4350 load as above:

Fitting

the Bolt

As part of the action

truing process, I decided to ensure a tight fit between the bolt

and receiver by adding and machining four small weld beads,

instead of the traditional sleeving process. If the welds are

made at the right places, the bolt can move freely when

retracting the bolt, but will lock up with a near perfect fit

when in battery.

I started by very

carefully measuring the bolt raceway with a Starrett snap gage.

In particular, I was sure to measure the raceway at both bearing

points: near the bolt head, and back near the bolt handle. I

found nearly a 0.002” difference between the diameters in the

action. Once these were measured, checked, and recorded, I

proceeded to the welding process.

I welded a very light

bead on the bolt in the four places that will contact the

bearing surfaces on the action. I used my Miller TIG welder and

a standard S type steel TIG filler rod to make these beads. My

research indicated that welding CrMo (4140) type steel with S

TIG rod was OK. I was very careful not to touch the bolt lugs,

or to over penetrate. I just wanted to add a slight amount of

metal to allow the machining process to generate that perfect

fit.

After welding, I

mounted the bolt in the four jaw chuck using a spud threaded

into the back of the bolt (1/2” X 13 TPI), and a live center in

the firing pin hole in the bolt face. The bolt was trued in the

same way that is used when squaring the bolt lug contact points

and truing the bolt nose and face. I then carefully turned each

pair of beads, front and back, to the measured bolt raceway

diameter minus 0.001”. A very easy process, and it fits

perfectly. The final touch was to put a little 800 grit lapping

compound from Brownells on the back of the lugs and the bolt lug

ears, and gently lap the lugs to the receiver and the bolt

raceway. Just a few strokes did it, being careful not to get the

lapping compound on the round part of the raceway, just the lug

recesses and bearing areas.

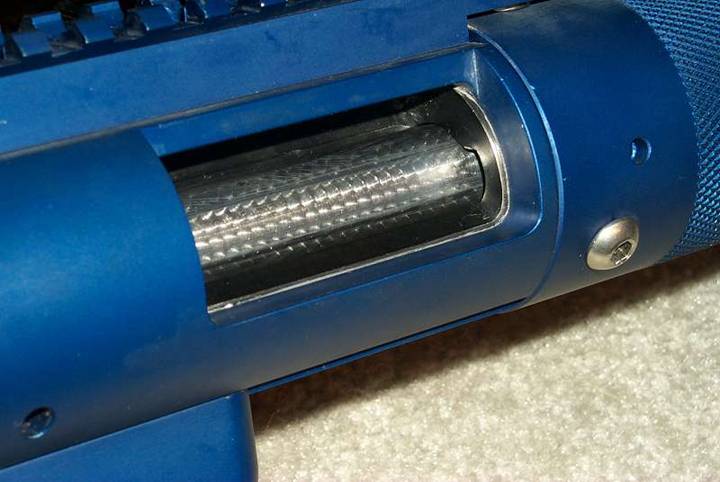

I jeweled the bolt on

my mill using a rotary table in the horizontal position, and a

Damascening tool from Brownells. Be sure to polish the bolt when

you are on the lathe, before the jewelling.

The pictures below

show the weld beads after machining:

Pinning the Sight Rail

I had a real problem

with the sight rail on the receiver sleeve shifting around under

recoil given the weight of that Nightforce scope. The flat head

screws are not enough to hold it tight, so I added some 3/16”

dowel pins to take up the load under recoil. I can now remove

the scope rail and replace it without any change in zero.

Here are a couple

shots of the pinned rail:

Tapered Sight Rail Wedges for

Long Distance Shooting

The tubegun is

primarily meant for use with iron sights, and has zero offset

angle in the sight rail. For long distance shooting, I needed to

add between 20 and 60 MOA in order to keep the scope within its

elevation adjustment range.

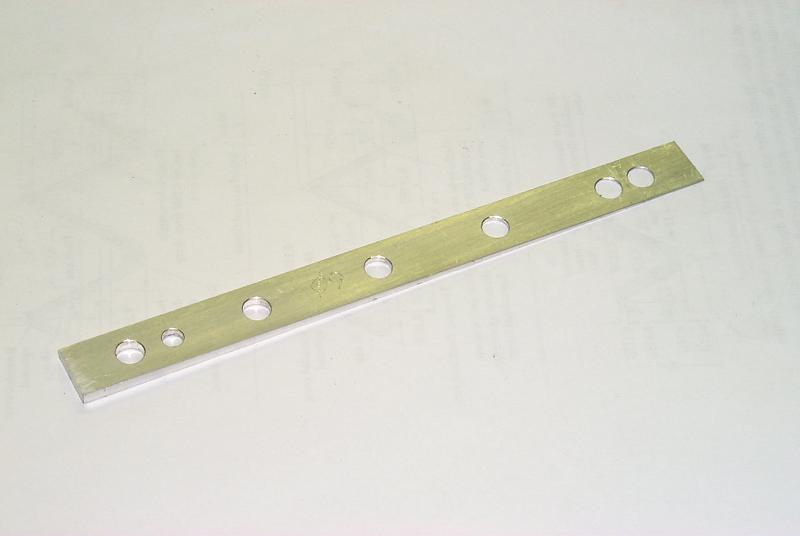

I designed and

machined these rail wedges, meant to go between the rail and the

receiver sleeve. It is machined with the required angle, and is

held captive by the rear dowel pin, between the rail and the

receiver sleeve. I machined it from 6061 aluminum. I actually

made three, one each at 20, 40, and 60 MOA. They can be added or

changed without loss of windage zero, due to the dowel pins.

Here is the 60 MOA rail:

Front and Rear Bag Rails

The tubegun is

designed for hand held shooting using iron sights. My shooting

at live varmints on off the bench requires the use of front and

rear bags. I designed and built a set front and rear bag rests

to accomplish this purpose.

First

Model for Front Rail- Aluminum Plate Design

The front rest is a

simple aluminum plate, made from 0.250” stock. It is about 3”

wide by 7” long. It is machined with a narrow ridge along the

centerline that fits into the hand stop slot in the tubegun

front hand guard tube. A set of T nuts made to fit the slot were

made from Delrin, and tapped 10-32. I have found that the rifle

likes to be supported as near the receiver as possible, so I

have slid the front rest plate as far back along this slot as

possible. This works perfectly in my Sinclair benchrest top.

Second

Model for Front Rail - Acetal (Delrin) Box Design

(4/15/06)

I was not completely

happy with the tracking performance of the aluminum plate

design, so I built up a three inch wide box using some slippery

acetal (trade name Delrin) plastic and some 10-32 capscrews. I

used the same T nuts to hold it to the TubeGun front hand grip

tube. This design tracks much better in the front rest, and is

very slippery, providing a smoother recoil characteristic and

making it much easier to return to battery after each shot.

Rear Bag Rail

The rear bag rail is

added to the Ironstone competition butt stock using the weight

rail as the attachment point. It is a two piece affair made from

aluminum, with a 5/8” rod that tracks in the rear bag perfectly.

New and

Stiffer Front Tube Assembly 4/26/07

I have never been

satisfied with the stock front hand guard tube assembly. While

perfect for offhand irons prone shooting, it was not stiff

enough for F-Class shooting from a rest, especially with heavy

contour barrels. There was quite a bit of bounce and flex,

making it a difficult to get consistent group performance. It

worked best with a very hard hold on the handgrip, and with the

butt stock hard into the shoulder. Free recoil did not work well

at all. I have been pondering how to make this assembly stiffer

so that the rifle will be able to perform well with a light hold

or free recoil technique.

While fitting the

rifle with a new Bartlien 5R, 8.5" twist, 1.25" straight

cylinder contour 6.5mm barrel, chambered in 6.5-284, I decided

to make a new hand guard and front stock assembly. The goal was

to make it as stiff as possible, and still keep the overall rifle

weight under the 10kg F-Class Open weight limit.

I settled on a

composite assembly, consisting of two aluminum tubes, 0.125" in

wall thickness, bonded together with epoxy, and then machined to

fit the receiver sleeve. The inner tube had an ID of 1.75", to

fit the Tube Gun receiver sleeve. The outer tube as a piece of

aluminum pipe, also 0.125" wall, that just fit over the smaller

tube, with about 0.030" clearance. Devcon 10110 steel filled

epoxy was used to bond the two together. After fitting to the

receiver, and providing clearance slots for the front scope

Picatinny rail, and the attachment groove for the Delrin front

rest support, a (very) large number of 0.75" holes were milled through

using an end mill. This did not weaken the assembly, and took

off nearly half the assembly weight.

The assembled rifle

now weighs 9.860kg. The front rest is very solid, with no flex

or bounce. I got a little fancy with the bead blasting of the

barrel, just for fun. Break-in will commence this weekend, and

results will be posted back here..

|