|

Latest Information

12/31/07 - .223AI F-Open 600

Yard Rifle

The

223AI has now morphed (again!) from a stock Savage 12FV in .223 Remington

into a F-Class Open starter rifle for my wife.

The Bell

and Carlson aftermarket stock was changed out for a MBR style

synthetic model from Sharp Shooters Supply two years ago.

At the

same time, I had also changed out the factory Accutrigger for a

SSS unit, as the factory trigger had gotten unreliable, and

would fail to cock, even when adjusted to over 1.5 pounds.

Apparently, this is not uncommon for the stock Savage

Accutriggers after a lot of use. The SSS trigger is set at 1

pound, and breaks cleanly, with no tendency to AD.

The

factory bolt handle was changed out to a stock Savage large

handle.

The

Pac-Nor pre-fit barrel installed in 2003 had finally given up

the ghost after the 2006 prairie dog hunt in South Dakota. There

had been over 4000 rounds fired through the barrel before

accuracy started to drop noticeably. So, in addition to the new

stock and trigger, the rifle was fitted with a new Brux

cut-rifled barrel. The barrel contour was a bit larger than the

stock factory Savage, being 0.930" vs. 0.750 at the muzzle.

This barrel was exceptionally straight in the bore, and the view

through the borescope looked excellent. I must also note that

dealing with Ken at Brux was extremely pleasant, and the

delivery time was a stunning two weeks after he received

payment. I'll be buying more barrels from them, you can be

assured of that.

The reamer was from Dave Kiff at PTG. (Drawings

HERE). It was ground to

provide the same throat dimension as the re-throated Pac-Nor,

which was optimized for the 75 grain Hornady AMax.

The

barrel channel on the SSS stock was enlarged on the mill with a

carbide 1.125" router bit, and skim bedded with black dyed

Marine-Tex epoxy. A length of 1.125" outside diameter 4140 thin wall tubing was

used as a form for this skim bedding. (An unused down-tube from

a Reynolds tube set left over from my street bike frame building

days).

A

Farrell 20 MOA Picatinny style base was bedded to the action

with Devcon 10110, and then pinned to the receiver with two

0.125" dowel pins to ensure that it never shifts.

Current

configuration for this rifle:

|

Caliber |

.223 Remington

Ackley Improved |

|

Barrel |

Brux

Stainless, 30 finished length, 4 groove, 1 : 8 twist,

1.050" for 2", then straight taper to 0.930" at the

muzzle |

|

Reamer |

Dave Kiff of

Pacific

Tool and Gauge .223AI, 0.250 neck, 0.105 freebore,

optimized for 75 AMax |

|

Receiver |

Savage 12FV, converted to single shot with shop made

follower |

|

Trigger |

Sharp

Shooters Supply Competition model |

| Stock |

Sharp

Shooters Supply MBR style synthetic |

| Scope rail |

Farrell 20MOA

Picatinny style, model SAV-RTS-1-20 |

| Scope |

Burris Black

Diamond 8-32X50, 30mm tube |

|

Rings |

Leupold QRW high, 30MM |

| Weight |

19.5

pounds |

Break-in at the range today went

exceptionally well. There was zero, and I mean zero, copper

fouling, even on the first few shots. The shoot one, clean one

routine was not necessary. This is the fastest break-in I have

ever experienced. A solid testimony to the quality of the Brux

barrel.

The ammo used was the standard accuracy

load for the old Pac-Nor barrel: 25.5 grain VVN140, 75 AMax, WSR

primer, 223AI fireformed cases from LC brass. Five shot groups

were all under 0.5" at 100 yards. A total of thirty rounds were

fired.

Next steps are to do some

load development. The goal is to repeat the 5 shot grouping in

the 3's of the original Pac-Nor barrel, and achieve a low

velocity SD so that the load will be a good performer at 300 to

600 yard F-Class competitions.

Archival Information

Original

Postings

August

2003

.223 Remington

Ackley Improved Re-barreling Project

This fall I

purchased a 27 stainless steel super-match grade barrel, 1:8

twist from Pac-Nor. My intent was to be able to shoot the heavy

(75 and 80 grain) VLD bullets very accurately, at reasonable

velocities. The standard .223 Remington cannot really drive the

heavy bullets more than about 2700 FPS without high pressures. I

wanted a load that would drive a 75 grain AMAX or an 80 grain

Berger VLD at about 2900-3000 FPS, at sub-MOA accuracies.

Chris and Penny at

Pac-Nor really took good care of me, and did a great job with

the barrel, which was chambered and pre-fit for the Savage

action very nicely. It took only a Savage barrel nut wrench, a

barrel vice (two chunks of 2X4 cross drilled with a 1 hole),

two go/no go gauges, and about 10 minutes to remove the factory

barrel and mount the Pac-Nor barrel.

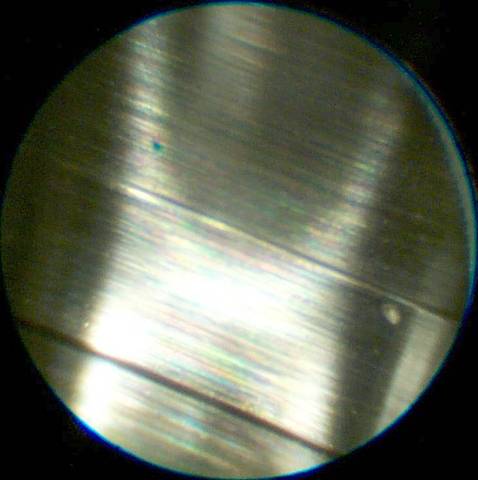

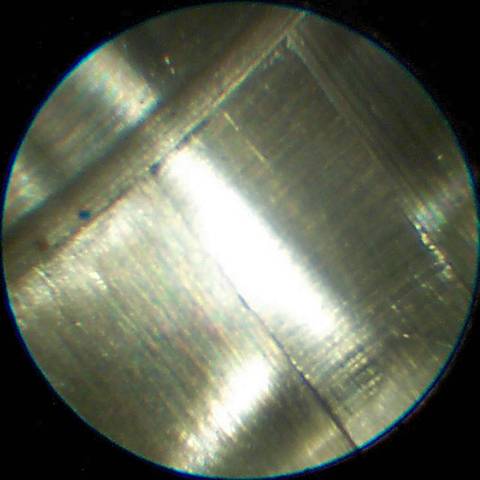

Here are some

pictures taken through my Hawkeye borescope with a digital

camera. They really show off the exceptional quality of the bore

and the throat on this barrel. I liked this barrel so much, I

ordered another SSSM from Pac-Nor for fitting to my 220 Swift by

a local smith.

This is a shot of the

bore of the brand new Pac-Nor SSSM .223 Remington Ackley Improved. This picture

was taken with a Kodak DC290 digital camera through a Hawkeye borescope:

This is the throat of the same barrel.

Note the absence of any significant tooling marks. This barrel shoots very, very

well:

This barrel lived

up to my expectations. The performance with the VLDs was

consistently one third MOA or less, with 0.6 5 shot groups at

200 yards the norm. However, the throat length was a bit too

short, and the VLDs were set into the case a bit too far,

limiting the amount of powder volume that was available. I

decided to send the barrel back to Pac-Nor and have them extend

the throat out by about 0.100.

Here is a picture

of the Savage with Pac-Nor barrel installed and the Weaver T36

scope:

UPDATE:

10/18/03

I just had the

throat lengthened at Pac-Nor by about 0.100 in order to be able

to seat the heavy 75 and 80 grain VLD bullets properly. The

original throating from Pac-Nor was for the lighter bullets, and

the VLDs were seating too far into the case, reducing the volume

available for powder. I had to increase the powder charge

(VVN140 and IMR4895) by 1.0 grain to get the barrel time and

velocity back to the original accuracy load levels. The rifle

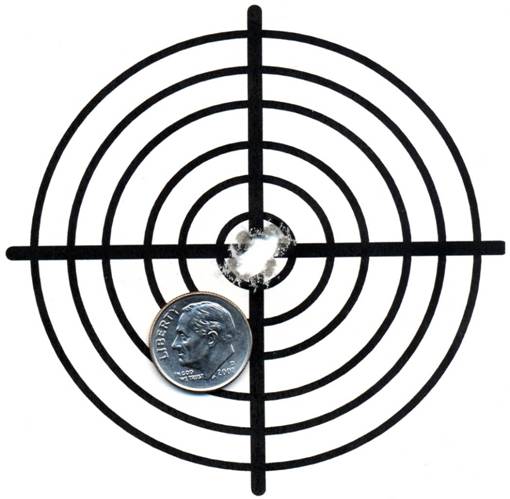

shoots even better than before. Here is a typical 5 shot group

from todays session, at 100 yards. I will post the 200 yard

data as it becomes available.

Re-throated Pac-Nor SSSM 27 .223 Ackley Improved, 1:8 twist,

COL 2.525

75

grain Hornady Amax, 25.5 grains VVN140, CCI BR4 primer, Lake

City brass, fire formed

5

shot group @ 100 yards, 0.28

Average 2948 FPS, extreme spread 60 FPS, standard deviation 25

FPS

UPDATE:

10/27/03

The performance at

200 yards with the Hornady AMax was very, very good, and I doubt

that it can be much better. The rifle clearly is limited only by

the performance of the loose nut squeezing the trigger. With an

extreme spread of only 51 FPS (30 shot aggregate), the expected

vertical error is less than 3 at 500 yards. This should make

for a very nice prairie dog rifle out to 500+ yards.

Re-throated Pac-Nor SSSM 27

.223 Ackley Improved, 1:8 twist, COL 2.525

75 grain Hornady Amax, 25.5 grains VVN140, CCI BR4 primer,

Lake City brass, fire formed

5 shot group @ 200 yards, 0.476

Average 2938 FPS, extreme spread 51 FPS, standard

deviation 12 FPS

Load and performance information on my .223 Remington Ackley

Improved project rifle Includes some

optimum barrel time estimates and a list of the best shooting

loads to date. Note that there are two pages of data, one for

the barrel as originally received from Pac-Nor, and one after

the throat was extended about 0.100 |